General-Purpose Hot Stamping Foil for Graphics, Labels, and Packaging Printing

PP Series General Purpose Hot Stamping Foil

Hot stamping foil plays a vital role in enhancing the appearance, perceived value, and durability of products. Whether it's for graphic applications, labeling solutions, or packaging printing, general-purpose hot stamping foil delivers exceptional versatility and performance. This article explores the benefits, applications, materials, and market trends of hot stamping foils used across multiple industries.

What is Hot Stamping Foil?

Hot stamping foil is a thin film used to transfer aluminium or pigmented colour designs to a substrate via a stamping process. It provides a high-quality metallic, pigment, or holographic finish. This printing technology is extensively used in packaging printing, label decoration, and graphic design for its ability to produce premium effects and lasting impressions.

Benefits of General-Purpose Hot Stamping Foil

General-purpose hot stamping foil is designed to be compatible with a wide variety of substrates, making it a popular choice for businesses seeking both aesthetic appeal and cost-efficiency. Key advantages include:

Versatility: Suitable for a wide range of materials, including coated papers, uncoated papers, plastics, and synthetic films.

Enhanced Visual Appeal: Adds metallic sheen, gloss, and vibrant color to packaging, labels, and printed graphics.

Brand Differentiation: Used to create premium-looking packaging and branded labels that stand out on the shelf.

Durability: Offers excellent scratch resistance, UV stability, and chemical resistance.

Eco-Friendly Options: Available in recyclable, solvent-free, and PVC-free variants to support sustainable packaging goals.

Common Applications

Graphics Printing

● Used in business cards, brochures, greeting cards, and magazine covers.

● Adds a luxurious, tactile effect that elevates graphic design projects.

Label Printing

● Common in wine and beverage labels, cosmetic packaging, and product branding.

● Enhances visual identity and conveys a sense of premium quality.

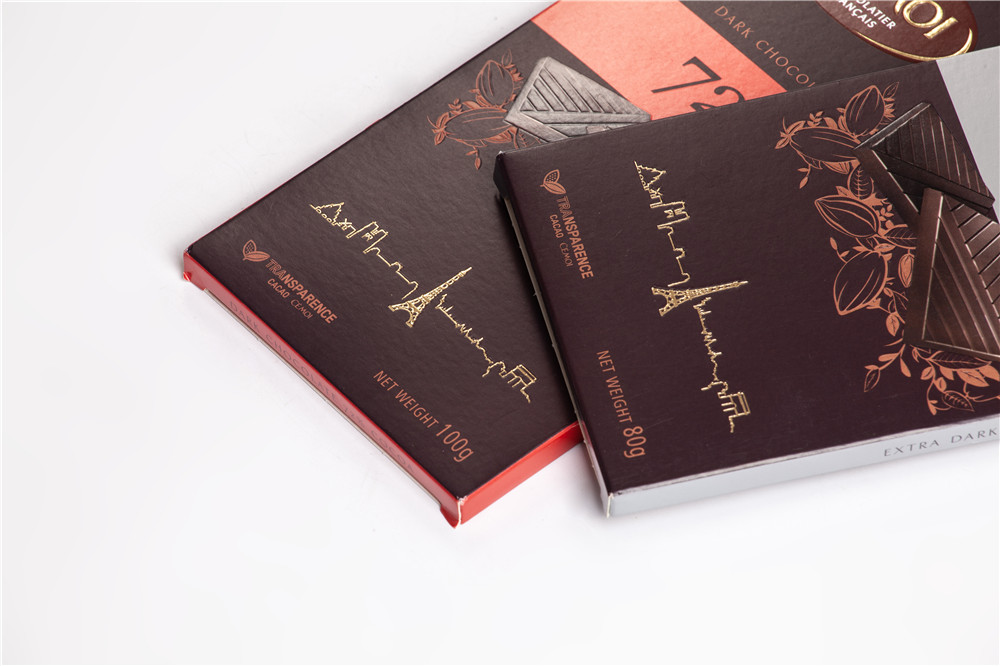

Packaging Printing

● Widely used in luxury packaging, gift boxes, retail packaging, and pharmaceutical cartons.

● Offers both decorative and functional benefits, including brand security and anti-counterfeiting.

General purpose hot foil, versatile for various graphic substrates

Types of Hot Stamping Foils

There are several types of foils tailored for different end-uses, but general-purpose hot stamping foil bridges the gap between specialty and flexibility:

Metallic Foils: Provide a brilliant, mirror-like finish in gold, silver, copper, and more.

Pigment Foils: Offer matte or glossy non-metallic colors suitable for a variety of surfaces.

Holographic Foils: Feature unique 3D effects that change with light and angle—perfect for eye-catching designs.

Clear and Security Foils: Transparent foils used for overlays and anti-counterfeiting measures.

Materials and Substrate Compatibility

Hot stamping foils consist of multiple layers, including a release layer, lacquer, metal (if metallic), adhesive, and a PET carrier film. They are engineered for adhesion to different substrates:

Paper and Board: Common in commercial printing and retail packaging.

Plastic Films: Used in flexible packaging and labeling for cosmetics.

Textiles and Leathers: Applied in branding, fashion tags, and promotional merchandise.

Hot Stamping Process: How It Works?

Preparation: Select the appropriate foil type and prepare the metal stamping die.

Application: The die is heated and pressed onto the foil and substrate.

Transfer: Under heat and pressure, the decorative layer is released and transferred onto the material.

Finishing: The result is a smooth, detailed print that resists smudging and fading.

Market Trends and Sustainability

The global hot stamping foil market is growing due to increasing demand in consumer goods, cosmetics, beverages, and luxury product segments. Brands are opting for eco-friendly foils that minimize environmental impact without compromising design quality.

With digital printing and automated hot stamping technologies on the rise, hot stamping is becoming more accessible for small to medium businesses. Moreover, sustainable packaging trends are encouraging the use of recyclable and compostable substrates combined with low-waste foiling options.

Why Choose General-Purpose Hot Stamping Foil?

For manufacturers, printers, and designers looking for a reliable, cost-effective decorative finish across various applications, general-purpose hot stamping foil is the go-to solution. It strikes the perfect balance between performance and affordability, enabling consistent results with high-speed production capabilities.

Choosing the Right Supplier

When selecting hot stamping foils, it's essential to work with a reputable foil manufacturer or supplier. Key factors to consider:

● Compatibility with printing equipment

● Substrate adhesion properties

● Available color and pattern options

● Durability and resistance to wear

● Compliance with safety and environmental standards

Some leading brands offer custom hot stamping foils tailored to specific branding and product needs.

Conclusion

General-purpose hot stamping foil continues to be a cornerstone of modern printing technology across graphics, labels, and packaging. With its ability to transform ordinary surfaces into high-impact visuals, hot stamping remains an indispensable tool in marketing and product presentation. Its widespread usage in various industries underscores its value as both an aesthetic enhancer and a branding powerhouse.

Whether you're in commercial printing, product labeling, or luxury packaging design, incorporating general-purpose hot stamping foil into your print solutions can elevate your brand and meet consumer expectations for quality and style.